Our pursuit of perfection

Listening to vinyl is about noticing the details. The same goes for building turntables. Building a great turntable takes time, and much of this time is spent calibrating, measuring, and testing.

Quality control is just as much about people as it is about parts. Abby Kaiser, our production manager, explains:

" We encourage and expect all U-Turn assembly technicians to be inspectors and problem solvers. They are responsible for catching abnormalities and helping to come up with solutions as soon as problems occur. We want everyone to be mindful of the quality of every part they are working with - down to the most basic things like screws.

Quality control needs to happen as soon as possible in the production process so that we can avoid waste and rework. That's why everything that gets checked at Final Inspection has already been looked at and tested at least once earlier on the line."

The measurements and tests we conduct during the build process are the heart of our quality program. Final Inspection is just an opportunity to double-check our work. Here is a glimpse into a few of those crucial points during the manufacturing process:

Tonearm Bearing Friction

In order to accurately track record grooves, the tonearm needs to be free to move across the record's surface with minimal friction. Our tonearm uses a gimbal bearing, which moves across both a horizontal and vertical axis. We test each axis independently by applying force using a fine wire. This serves as a measure of friction within the bearing. If a tonearm fails either the horizontal or vertical friction test, then the arm will either be re-calibrated or re-built and again put through friction testing.

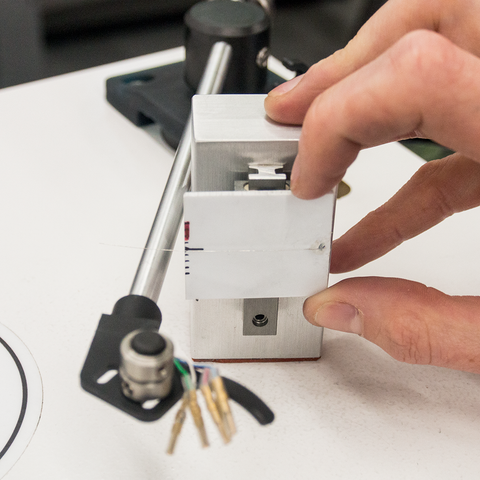

Cartridge Alignment & Calibration

Your cartridge is responsible for "reading" the grooves of your records and then translating the resulting vibrations into an audio signal. To do its job well, the cartridge must be properly aligned and must apply the correct amount of force (vertical tracking force or "VTF" for short) to the record. We take care of these adjustments at the factory so that every turntable is ready to play straight out of the box. To do this, we have machined a set of aluminum tools to accurately align the cartridge body and adjust VTF. Each model of cartridge we offer requires its own tool.

Platter Flatness

The platter should remain level as it rotates. This ensures consistent contact between stylus and record, and also helps to prevent wow & flutter. We require all of our platters to have <0.5mm of vertical movement per rotation, and we use a digital microscope to ensure that platters meets this spec. During the main assembly process, we test each individual platter and spindle (the part that the platter sits on) independently of one another. Once a platter is paired with a spindle, we will then test the two parts together. This two-step process allows us to account for very small variations between parts.

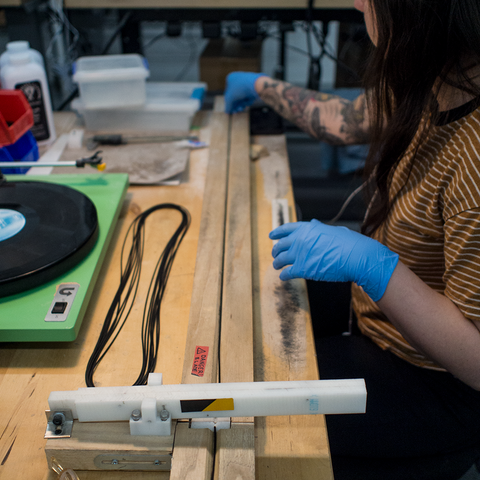

Belt Fabrication

In order to ensure proper speed consistency and motor noise isolation, drive belts must be the correct length, width, and elasticity. We start with a long spool of nitrile rubber, and use a custom cutting tool to ensure that each belt segment is the correct length. We then bond the ends of the segment together and sand the joint so that there is no seam. Once bonded, we install the belt on a reference turntable and measure frequency deviation and wow & flutter with a test record. For good measure, we will test this belt again once it is paired with a freshly built turntable.

Final Inspection & Listening Test

When we finish assembling a turntable, we "burn-in" the motor and drive system for some time before putting the table through Final Inspection. At this point, we are just double-checking things like main bearing play, platter wobble, azimuth (headshell angle), tonearm motion, VTF, channel testing, and cartridge alignment. We use a test record to measure trackability and motor noise. Upon completion of inspection, we clean the stylus and do a final check for cosmetic blemishes before sending the turntable to its new home.

Quality is not an act. It's a habit.

Quality doesn't start and stop at the factory. There are 40+ custom precision parts that go into a single Orbit Turntable. Each part has its own critical dimensions and tolerances. Every time we receive a shipment of parts from a supplier, we measure these dimensions and perform assembly tests to ensure that all parts function as intended. Making sure that all the pieces fit together is an ongoing collaboration between our assembly technicians, our engineers, our suppliers, and even our customer support team.

We strive for zero defects. But of course, defects do occur in manufacturing. That's part of the reason we offer a two-year warranty and lifetime product support with all of our turntables. We are proud of our low defect rates, but we are never satisfied with the status quo. Improvement is a continuous process that everyone at U-Turn actively participates in.